Structural Insulated Panels (or SIPs) are a high performance building system that sandwiches insulation, bonded between two boards - usually oriented strand board (OSB). There are many forms of proprietary SIPs systems available – all of which utilise different cores and thicknesses of board, however, as the original Kingspan TEK™ Delivery Partner, SIPS@Clays supplies the market leading Kingspan TEK™ Building System, which you can read more about here.

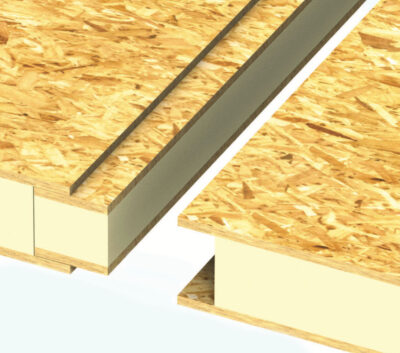

Kingspan TEK™ utilises Kingspan’s high performance, fibre-free rigid thermoset Urethane Insulation for the core of the SIP panels, which is autohesively* bonded and sandwiched between two sheets of oriented strand board (OSB/3). This process is exceptionally reliable and vastly superior to the ‘secondary adhesion’ process often used in the manufacture of inferior SIPs panels.

Housing currently contributes to 27% of Britain’s carbon dioxide emissions. However, the insulating properties of SIPs have now made it possible to build cost-effective, zero carbon homes and buildings that are ready for the future.

SIPs are one of the most ecologically friendly building materials on the market. They can help homeowners to dramatically reduce their heating bills and significantly increase available living space in the build.

The Kingspan TEK™ Building System uses a unique jointing system (Splines), which is made, in essence, from a ‘mini’ SIPs panel. It interlocks two panels whilst rigorously maintaining the insulation layer. Unlike timber frame construction, SIP panels do not rely on stud walls at 400/600mm centres in order to maintain the structure.

This innovative jointing system helps to lower the overall wall U-value compared with other forms of construction such as brick and block or Insulated Concrete Formwork (ICF), minimises air leakage at connection joints and reduces thermal bridging.

Structural or intermediate floors are an integral part in any SIPs structure and to achieve the best installation results, the floors supplied by SIPS@Clays can be constructed in a couple of ways.

The first is a timber I-joist — these have a vertical web made from particle board and a top and bottom flange made of plywood. Following a simple set of guidelines they can be cut and trimmed on site and drilled as required.

The simple design characteristics of these joists means that, together with the use of the ‘hospital’ pack which is provided with the kit, small tweaks, such as remediation work to damaged joists , trimming the size of an oversized floor or changing the aperture of the staircase for example, can easily be carried out on site.

Alternatively, open web joists can be used. These have a solid top and bottom flange but with a metal vertical web. Open web joists, whilst making your electrician’s and/or plumber’s jobs a little easier (as holes don’t need to be drilled for pipes and cables) cost around 50% more than engineered I-joists. Usually this over cost in using open web joist is more than the labour cost of making the required holes in the I-joists. We suggest that you check with your electrician and plumber to see whether they will offer a reduced price based on using metal web joists. As open web joists are unique to their length and complex in nature, they cannot be resized, cut or readily replaced on site.

Depending on the span and design criteria, both options range from 200mm to 360mm deep and will be topped with 22mm Egger Protect structural floor deck, giving rigid, squeak-free floors up to 5.5m in length.

We would always recommend engineered I-Joists as they suit the Kingspan TEK™ SIPs building system and help maintain a smooth workflow on site.