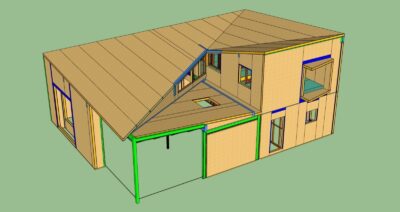

Unlike many other SIPs providers, SIPS@Clays have our own in-house design team. We work closely with you or your chosen architect to translate your planning drawings into a SIP friendly design. Using 3D CAD systems, which are a necessity when creating geometrically complex structures, we are able to design in elements that will enhance and design out elements that may impede your project. So, even if your architect isn’t an expert in a SIP building system, we will help you to achieve your perfect home, with value engineering and cost saving efficiencies built in.

It is a common misconception that SIPs structures are boxy and boring, in fact it’s quite the opposite. The flexibility in design and ease of constructions means that anything is possible.

In short, the answer is NO! The versatility and flexibility of building with SIPs means that any design is possible and there is no design or cost benefit of designing around standard SIPs panel sizes. In fact, it often limits what can be achieved and can lead to unhelpful compromise of window and door sizes and locations which no doubt have timber posts and panel splits occurring in inappropriate or awkward locations.

It is important to note that if you do choose to use standard size SIP panels, care should be taken when architect’s plans are submitted for planning approval.

Speak to our in-house design team who will provide best practice advice and guidance.

SIP panels can easily span 3.5m between support i.e. ridge, purlin or wall, and as the SIP roof panels are structural, there is no need for traditional roof trusses. Unlike traditional systems, SIPs allows greater design flexibility, and, without the limitations of trusses in the finished roof space, a SIPs design provides spacious ‘room in roof’, attic rooms to maximise space and add value to a property.

We utilise glulam beams for ridge/purlins which really help bring the 'WOW' factor to vaulted spaces and rooms in the roof.

Large openings in gables are usually created by a Glulam frame that is fitted within the SIPs wall around the gable opening. Our in-house design team will work closely with your or your chosen architect to determine your requirements; sizing the frame to maximise window space and natural sunlight whilst expertly hiding the Glulam roof support beams above.

The long spans of floor joists and roof panels lend themselves perfectly to this type of design, with the I-joist floor system effectively spanning 5.9m (300mm deep joists at 400mm centres). If wider spans are required, a steal beam can be integrated and hidden in the floor build-up.

The result of creating large open plan designs though, is an overall loss of ‘racking’. Internal walls contribute to the overall stability of a structure and fewer internals could mean steel portal frames may be required to build the rigidity back in.

As part of our design and appraisal service, we will assess your plans, advising and recommending solutions to overcome potential issues.

SIPs structures are highly energy efficient and it is important to remember that when you are building a SIP home you are creating an airtight envelope - typically around 1.0m3 /hour/m2. It is therefore essential that you implement a ventilation strategy which should include the installation of a mechanical ventilation heat recovery (MVHR) system. As part of this strategy, it is important that pipework and duct route integration should be carefully considered with the floor joist layout and our design team will be able to advise on this and recommend areas for consideration

We would always recommend installing MVHR units for new build homes in order to maintain a constant flow of fresh air within the property, maintain air quality throughout and keep your heating costs to a minimum. These systems recycle heat around the house while expelling moisture from bathrooms/kitchens. SIPs extensions usually do not require MVHR units unless the existing property is airtight (in which case you may already have an MVHR).

As is often the case, especially with rural sites, access via narrow country lanes is the only option. SIPs are the ideal building solution if your chosen plot has access issues, is small or sloping or has traffic restrictions.

It is important to remember that in order to get your fabricated frame to site, you will require the correct plant to unload the panels from our delivery vehicle. A tele-handler will be required to manoeuver the wall and roof SIP panels, while a crane or Hiab will be needed to lift the heavy, long roof panels into place.

As the SIP panels provide both structure and insulation, there is no need for the external finish to provide any structural support, other than to support itself. This means that you can use modern, lightweight cladding systems, including timber, render board, rainscreen cladding systems or even brick/stone slips.

The chosen façade treatment is fitted via a min 25mm tanalised timber batten fixed to the outside of the SIPs frame. It is important to note that the Kingspan TEK™ Building System requires a ventilated cavity between panels and cladding.

The frame will have been left with a breather membrane to help protect your building from the elements until brickwork is applied which will stop damp from getting into the panels.

Heavier cladding options, such as an external skin of brick or stone, will require building off their own foundations. Where external skin extends above a lower roof, to meet a higher roof (or similar), steel will need to be designed into the structure to provide support for this. Our in-house design team will highlight these areas and ‘design in’ some steel support that ensures your SIPs envelope is continuous. This also helps to maintain air tightness.

A similar detail is required on roof panels; for instance 25mm min vertical batten (to allow water to run off the panels) and a counter batten to affix roof tiles/slates, etc.

Internally services are hidden within a service void. This is typically created with a min 25mm x 50mm timber batten.

A second layer of plaster board chased to accommodate services can also provide the service ‘void’. This gives the wall a more solid feel.

Where services are not required, plasterboard can be fitted directly to the SIPs panels.

This service void is wide enough to house your electrical services. Larger pipes such as MVHR ducts or soil waste pipes should be hidden within internal timber frame walls or located in corners to minimize their appearance.