Today, many buildings are built with a traditional timber frame structure and this trend is growing as Building Regulations / Standards strive for better thermal performance and the construction industry moves towards faster and lighter methods of construction. Structural Insulated Panel (SIP) technology is the next generation of timber based construction.

In the UK and Ireland, demand for offsite construction methods such as SIPs is growing rapidly. This is being driven by factors such as the availability of on-site skills being at an all time low.

Building Regulations / Standards are demanding much higher levels of energy efficiency. This is challenging many traditional construction systems and, in some instances, forcing people to look at alternative ways of meeting the requirements more economically. Unparalleled energy efficiency combined with high build-speed and the low site wastage make the Kingspan TEK® Building System a very cost effective way of achieving and exceeding the thermal requirements of the Building Regulations / Standards.

The Kingspan TEK structural insulated panels (SIPs) building system is made up of two sheets of 15mm Oriented Strand Board (OSB) with a high performance, rigid urethane insulation core which is autohesively bonded to the OSB facings.

Available in 142mm and 172mm thickness, Kingspan TEK can be used to construct load-bearing and non-loadbearing walls, roofs and intermediate floors.

| Thermal Conductivity | Insulation core: 0.024 W/m.k OSB/3 facings. |

|---|---|

| Euroclass | The OSB/3 panel linings have a reaction to fire classification of D-s2, d0 to BS EN 13501-1: 2018. |

| Core | High performance fibre-free rigid urethane insulation manufactured with a blowing agent that has zero Ozone Depletion Potential (ODP). |

| Facings | 15mm Oriented Strand Board type 3 (OSB/3). |

| Board Size | Width: 1,220 mm Length: Up to 7.5 m Depth: 142 mm / 172 mm Note that panels can fabricated down to a minimum of 200 mm x 200 mm to fit the design of the building. |

| Green Guide Rating | Wall and roof elements, constructed using the Kingspan TEK Building System in a 142 mm panel thickness, correspond to generic elements with 2008 BRE Global Green Guide Summary Ratings of A+ or A. |

SIPS@Clays recommends using 142mm panels together with an additional layer of internal insulation, as opposed to 172mm panels. This is sensible because:

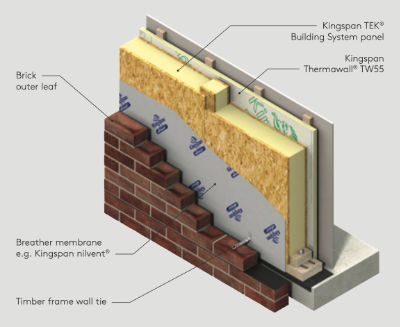

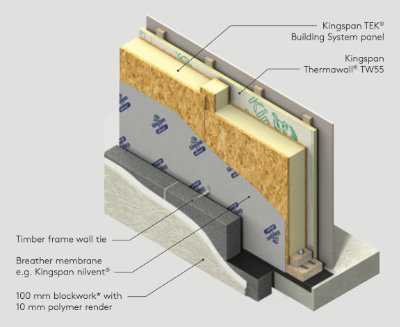

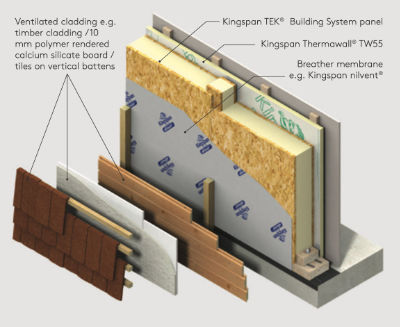

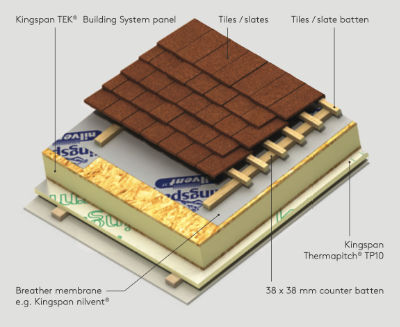

The U-values in the tables that follow have been calculated, under a management system certified to the BBA Scheme for Assessing the Competency of Persons to Undertake U-value and Condensation Risk Calculations, using the method detailed in BS EN ISO 6946: 2017 / I.S. EN ISO 6946: 2007 (Building components and building elements. Thermal resistance and thermal transmittance. Calculation methods) and using the conventions set out in BR 443 (Conventions for U-value calculations).

The U-values in the tables that follow are valid for the constructions shown in the details immediately above. Unless otherwise stated, the U-values quoted are based on an internal construction comprising a 3 mm plaster skim on 12.5 mm plasterboard fixed to 50 x 25 mm softwood timber battens. The external finishes are as specified in the examples themselves.

NB For calculations which do not feature additional internal insulation, a 4% bridging factor has been assumed for walls and 1% for pitched roofs. The thermal conductivity of the timber has been assumed at 0.12 W/mK.

NB Calculations assume that the use of a foil faced breather membrane yields an airspace thermal resistance of 0.54 m2K/W.

NB For the purposes of these calculations the standard of workmanship has been assumed good and therefore the correction factor for air gaps has been ignored. NB The figures quoted are for guidance only. A detailed U-value calculation together with condensation risk analysis should be completed for each individual project.

NB If your construction is any different to those specified and / or to gain a comprehensive U-value calculation along with a condensation risk analysis of your project please consult the Kingspan Insulation Technical Service Department for assistance (see rear cover for details).

| U-Values for Kingspan TEK® Building System Walls with Various Thicknesses of Additional Insulation and Different Breathable Membranes | |||

|---|---|---|---|

| Thickness of Kingspan TEK® Building System Panels (mm) | Thickness of Kingspan Thermawall® TW55 (mm) | Standard Breathable Membrane U-value (W/m2K) | Foil Faced Breathable Membrane U-value (W/m2K) |

| 142 | 0 | 0.19 | 0.18 |

| 142 | 20 | 0.15 | 0.15 |

| 142 | 25 | 0.15 | 0.15 |

| 142 | 30 | 0.14 | 0.14 |

| 142 | 40 | 0.13 | 0.13 |

| 142 | 50 | 0.13 | 0.12 |

| 142 | 60 | 0.12 | 0.12 |

| 142 | 70 | 0.11 | 0.11 |

| 142 | 75 | 0.11 | 0.11 |

| 142 | 80 | 0.11 | 0.10 |

| 142 | 90 | 0.10 | 0.10 |

| 172 | 0 | 0.16 | 0.15 |

| 172 | 20 | 0.13 | 0.13 |

| 172 | 25 | 0.13 | 0.12 |

| 172 | 30 | 0.12 | 0.12 |

| 172 | 40 | 0.12 | 0.11 |

| 172 | 50 | 0.11 | 0.11 |

| 172 | 60 | 0.11 | 0.10 |

| 172 | 70 | 0.10 | 0.10 |

| Kingspan TEK® Building System Walls with 10 mm Polymer Rendered 100 mm Dense Blockwork Outer Leaf | |||

|---|---|---|---|

| Thickness of Kingspan TEK® Building System Panels (mm) | Thickness of Kingspan Thermawall® TW55 (mm) | Standard Breathable Membrane U-value (W/m2K) | Foil Faced Breathable Membrane U-value (W/m2K) |

| 142 | 0 | 0.19 | 0.18 |

| 142 | 20 | 0.15 | 0.15 |

| 142 | 25 | 0.15 | 0.14 |

| 142 | 30 | 0.14 | 0.14 |

| 142 | 40 | 0.13 | 0.13 |

| 142 | 50 | 0.13 | 0.12 |

| 142 | 60 | 0.12 | 0.11 |

| 142 | 70 | 0.11 | 0.11 |

| 142 | 75 | 0.11 | 0.11 |

| 142 | 80 | 0.11 | 0.10 |

| 142 | 90 | 0.10 | 0.10 |

| 172 | 0 | 0.16 | 0.15 |

| 172 | 20 | 0.13 | 0.13 |

| 172 | 25 | 0.13 | 0.12 |

| 172 | 30 | 0.12 | 0.12 |

| 172 | 40 | 0.12 | 0.11 |

| 172 | 50 | 0.11 | 0.11 |

| 172 | 60 | 0.11 | 0.10 |

| 172 | 70 | 0.10 | 0.10 |

| Kingspan TEK® Building System Wall Panels with Ventilated Cladding | |||

|---|---|---|---|

| Thickness of Kingspan TEK® Building System Panels (mm) | Thickness of Kingspan Thermawall® TW55 (mm) | U-value (W/m2K) | |

| 142 | 0 | 0.20 | |

| 142 | 20 | 0.16 | |

| 142 | 25 | 0.15 | |

| 142 | 30 | 0.15 | |

| 142 | 40 | 0.14 | |

| 142 | 50 | 0.13 | |

| 142 | 60 | 0.12 | |

| 142 | 70 | 0.12 | |

| 142 | 75 | 0.11 | |

| 142 | 80 | 0.11 | |

| 142 | 90 | 0.11 | |

| 172 | 0 | 0.17 | |

| 172 | 20 | 0.14 | |

| 172 | 25 | 0.13 | |

| 172 | 30 | 0.12 | |

| 172 | 40 | 0.12 | |

| 172 | 50 | 0.11 | |

| 172 | 60 | 0.11 | |

| 172 | 70 | 0.10 | |

| Kingspan TEK® Building System Wall Pitched Roofs | |||

|---|---|---|---|

| Thickness of Kingspan TEK® Building System Panels (mm) | Thickness of Kingspan Thermapitch® TP10 (mm) | U-value (W/m2K) | |

| 142 | 0 | 0.19 | |

| 142 | 20 | 0.16 | |

| 142 | 25 | 0.15 | |

| 142 | 30 | 0.15 | |

| 142 | 40 | 0.14 | |

| 142 | 50 | 0.13 | |

| 142 | 60 | 0.13 | |

| 142 | 70 | 0.12 | |

| 142 | 75 | 0.11 | |

| 142 | 80 | 0.11 | |

| 142 | 90 | 0.10 | |

| 172 | 0 | 0.16 | |

| 172 | 20 | 0.13 | |

| 172 | 25 | 0.13 | |

| 172 | 30 | 0.12 | |

| 172 | 40 | 0.12 | |

| 172 | 50 | 0.11 | |

| 172 | 60 | 0.11 | |

| 172 | 70 | 0.10 | |